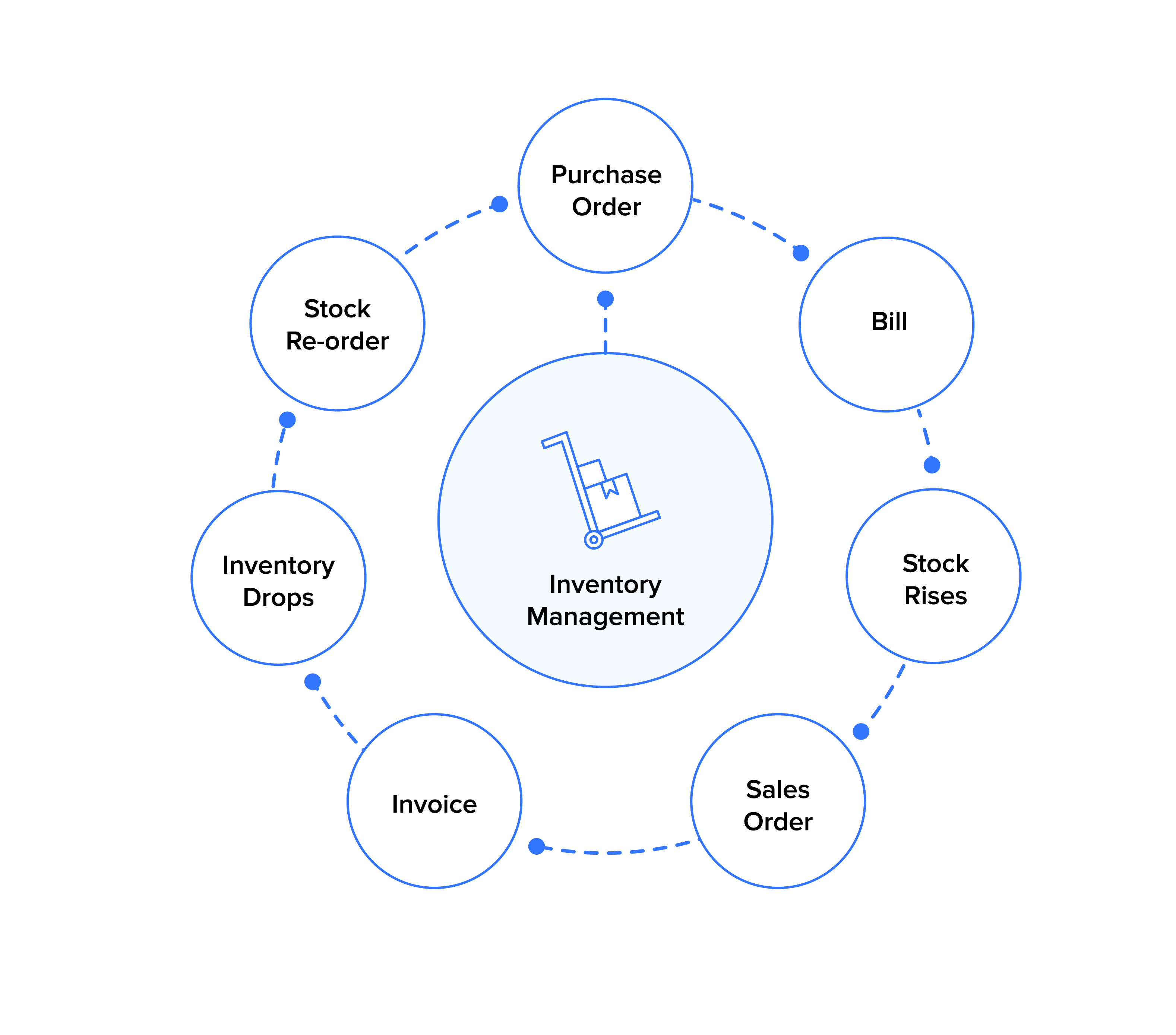

Business inventory ordering plays a pivotal role in supply chain management, directly impacting profitability and customer satisfaction. This comprehensive guide delves into the intricacies of inventory management, providing insights into effective techniques, optimization strategies, and supplier relationship management.

By mastering the art of inventory ordering, businesses can optimize their operations, reduce costs, and enhance their overall efficiency. This guide will equip you with the knowledge and tools necessary to establish a robust inventory management system that drives success.

Inventory Management Techniques

Inventory management is a critical aspect of business operations, ensuring the availability of necessary items while minimizing costs and preventing shortages. Various techniques are employed to optimize inventory levels, each with its own advantages and disadvantages.

ABC Analysis

ABC analysis classifies inventory items into three categories based on their annual usage value. A-items are the most valuable and require the highest level of control, while C-items are the least valuable and can be managed with less attention. This technique helps prioritize inventory management efforts and focus resources on the most critical items.

Economic Order Quantity (EOQ)

EOQ determines the optimal quantity of inventory to order at a time, considering factors such as demand, holding costs, and ordering costs. By minimizing total inventory costs, EOQ helps businesses optimize their inventory levels and reduce waste.

Just-in-Time (JIT) Inventory, Business inventory ordering

JIT inventory aims to minimize inventory levels by receiving items only when they are needed for production or sale. This technique requires close coordination with suppliers and efficient logistics to ensure timely delivery and prevent shortages.

Safety Stock Levels and Reorder Points

Safety stock levels are maintained to buffer against unexpected demand fluctuations or supply chain disruptions. Reorder points trigger the replenishment of inventory when stock levels reach a predetermined threshold. These measures help prevent stockouts and ensure continuous availability of essential items.

Inventory Optimization Strategies

Inventory optimization is crucial for businesses to minimize costs and enhance efficiency. By implementing effective strategies, companies can streamline inventory management, reduce waste, and improve customer satisfaction.

One key aspect of inventory optimization involves determining the optimal inventory levels to maintain. This can be achieved through techniques such as:

Safety Stock

- Maintaining a buffer of inventory to protect against unexpected demand fluctuations.

- Helps prevent stockouts and ensures uninterrupted operations.

Economic Order Quantity (EOQ)

- Calculates the optimal quantity to order at a time to minimize total inventory costs.

- Considers factors such as ordering costs, holding costs, and demand.

Just-in-Time (JIT) Inventory, Business inventory ordering

- Aims to have inventory arrive just when it is needed.

- Reduces inventory carrying costs and improves efficiency.

Technology plays a significant role in inventory optimization. Inventory management software can automate processes, provide real-time data, and generate insights to help businesses make informed decisions.

Examples of Successful Inventory Optimization Implementations

- Amazon:Uses advanced algorithms and predictive analytics to optimize inventory levels and reduce waste.

- Toyota:Implemented the Kanban system to streamline production and inventory management.

- Walmart:Leverages RFID technology to track inventory and improve supply chain efficiency.

Supplier Relationships and Management

Building strong relationships with suppliers is crucial for any business that relies on inventory. A positive supplier relationship can lead to better prices, shorter lead times, and improved quality. It can also help you to avoid disruptions in your supply chain.

There are a number of strategies you can use to evaluate and select suppliers. Some of the most important factors to consider include:

- Price

- Quality

- Reliability

- Flexibility

- Location

Once you have selected a supplier, it is important to manage the relationship effectively. This includes:

- Communicating regularly

- Monitoring performance

- Resolving problems quickly

By following these tips, you can build strong supplier relationships that will help you to improve your inventory management and overall business performance.

Negotiating Favorable Terms

When negotiating with suppliers, it is important to be prepared. You should know what you want and be willing to walk away if you cannot get it. It is also important to be respectful of the supplier’s needs. By following these tips, you can increase your chances of negotiating favorable terms.

- Do your research

- Be prepared to walk away

- Be respectful of the supplier’s needs

- Build a long-term relationship

Supplier Performance Monitoring

It is important to monitor supplier performance on a regular basis. This will help you to identify any problems early on and take corrective action. There are a number of different metrics you can use to measure supplier performance, such as:

- Delivery time

- Quality

- Price

- Flexibility

- Customer service

By monitoring supplier performance, you can ensure that you are getting the best possible value for your money.

Inventory Forecasting and Demand Planning

Inventory forecasting plays a critical role in inventory ordering by predicting future demand and optimizing inventory levels. Accurate forecasting helps businesses avoid stockouts, reduce excess inventory, and improve overall supply chain efficiency.Different forecasting methods exist, each with varying accuracy levels.

Common methods include:

Time Series Forecasting

Extrapolates historical demand patterns to predict future demand.

Causal Forecasting

Considers external factors (e.g., economic conditions, competitor actions) to predict demand.

Machine Learning Forecasting

Utilizes advanced algorithms to analyze complex demand patterns and make predictions.

Demand Planning Process

Developing and implementing a demand planning process is crucial for effective inventory management. This process involves:

Data Collection and Analysis

Gathering and analyzing historical demand data, market trends, and other relevant information.

Demand Forecasting

Utilizing forecasting methods to predict future demand.

Demand Segmentation

Grouping demand into categories based on product type, customer segment, or other factors.

Safety Stock Determination

Establishing buffer inventory levels to mitigate demand fluctuations and uncertainties.

Collaboration and Communication

Involving key stakeholders (e.g., sales, operations, finance) in the demand planning process.

Inventory Control and Monitoring

Establishing an effective inventory control and monitoring system is crucial for maintaining accurate inventory records, minimizing losses, and optimizing stock levels. This involves implementing robust processes and leveraging technology to track inventory movement and ensure data integrity.

Barcodes and RFID Tags

Barcodes and RFID (Radio Frequency Identification) tags play a significant role in inventory control and monitoring. Barcodes provide a simple and cost-effective way to identify and track individual items, while RFID tags offer advanced features such as real-time tracking and long-range scanning.

Regular Inventory Audits

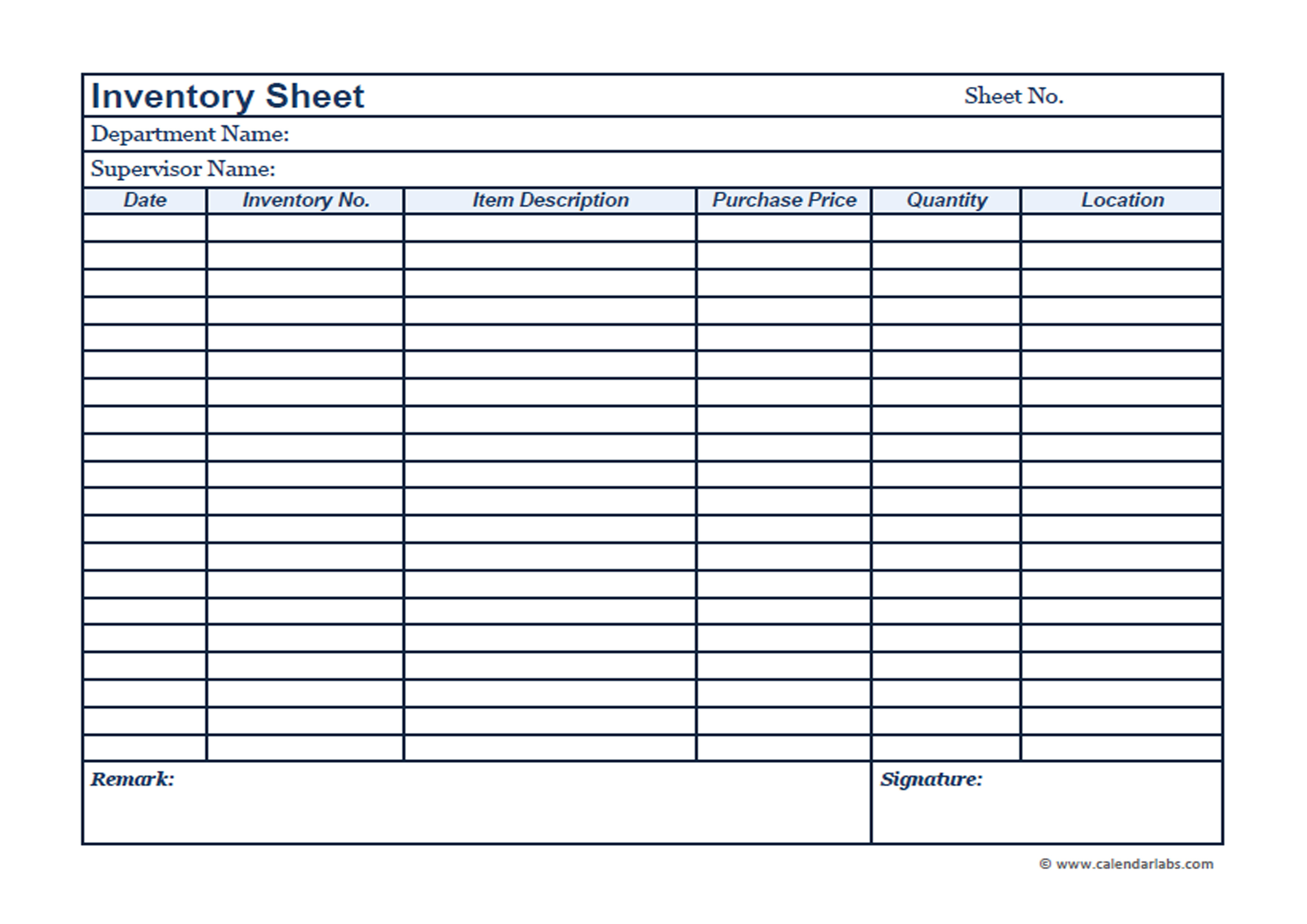

Regular inventory audits are essential for verifying the accuracy of inventory records and identifying discrepancies. These audits involve physically counting and reconciling inventory items against the system records. Discrepancies can be caused by various factors, such as theft, damage, or errors in data entry, and should be investigated and corrected promptly.

Inventory Reconciliation

Inventory reconciliation involves comparing inventory records with other relevant data sources, such as purchase orders, sales invoices, and production records. This process helps identify and resolve discrepancies, ensuring that inventory records are accurate and reliable.

Inventory Reporting and Analysis

Inventory reporting and analysis play a vital role in effective inventory management. It involves gathering, organizing, and interpreting data to gain insights into inventory performance, identify trends, and make informed decisions.

Comprehensive Inventory Reporting System

A comprehensive inventory reporting system provides a clear and concise overview of inventory levels, movements, and performance. It should include the following components:

- Inventory Summary Report:Provides a snapshot of overall inventory levels, including total inventory value, stock levels, and turnover rates.

- Inventory Detail Report:Lists individual inventory items, their quantities, locations, and other relevant information.

- Inventory Transaction Report:Records all inventory transactions, such as purchases, sales, and adjustments.

- Inventory Aging Report:Shows the age of inventory items, highlighting slow-moving or obsolete stock.

Key Metrics for Inventory Performance

To measure inventory performance, key metrics such as the following are used:

- Inventory Turnover Ratio:Measures how quickly inventory is sold and replaced.

- Days Sales of Inventory (DSI):Indicates the average number of days it takes to sell the entire inventory.

- Inventory Accuracy:Compares physical inventory counts to the records to ensure accuracy.

- Inventory Shrinkage:Measures the loss of inventory due to theft, damage, or obsolescence.

Analyzing Inventory Data

Analyzing inventory data helps identify trends and patterns that can inform decision-making. Techniques such as:

- Trend Analysis:Tracking inventory levels over time to identify seasonal fluctuations or changes in demand.

- ABC Analysis:Classifying inventory items based on their value and demand to prioritize inventory management efforts.

- Pareto Analysis:Identifying the few inventory items that contribute to a majority of the inventory value.

By analyzing inventory data, businesses can optimize inventory levels, reduce costs, and improve customer service.

Ending Remarks: Business Inventory Ordering

In conclusion, business inventory ordering is a multifaceted discipline that requires careful planning, execution, and continuous improvement. By implementing the strategies Artikeld in this guide, businesses can gain a competitive edge, improve customer service, and achieve operational excellence.

Expert Answers

What are the key inventory management techniques?

Common inventory management techniques include FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and ABC analysis, each with its own advantages and disadvantages.

How can I optimize my inventory levels?

Inventory optimization involves strategies such as demand forecasting, safety stock management, and the use of inventory management software to minimize costs and improve efficiency.

Why is building strong supplier relationships important?

Strong supplier relationships ensure reliable deliveries, favorable terms, and open communication, ultimately contributing to smooth inventory management.