Delving into the realm of business inventory online, this comprehensive guide unveils the secrets to efficient stock management for online businesses. With a keen focus on inventory management systems, optimization techniques, tracking and control measures, forecasting and planning strategies, and replenishment strategies, this guide empowers you to streamline your inventory operations and elevate customer satisfaction.

The seamless integration of technology and data-driven insights empowers online businesses to gain a competitive edge. By harnessing the power of inventory management systems, businesses can automate processes, minimize errors, and gain real-time visibility into their stock levels. Moreover, inventory optimization techniques enable businesses to strike a delicate balance between minimizing costs and meeting customer demands, ensuring optimal stock levels at all times.

Inventory Management Systems

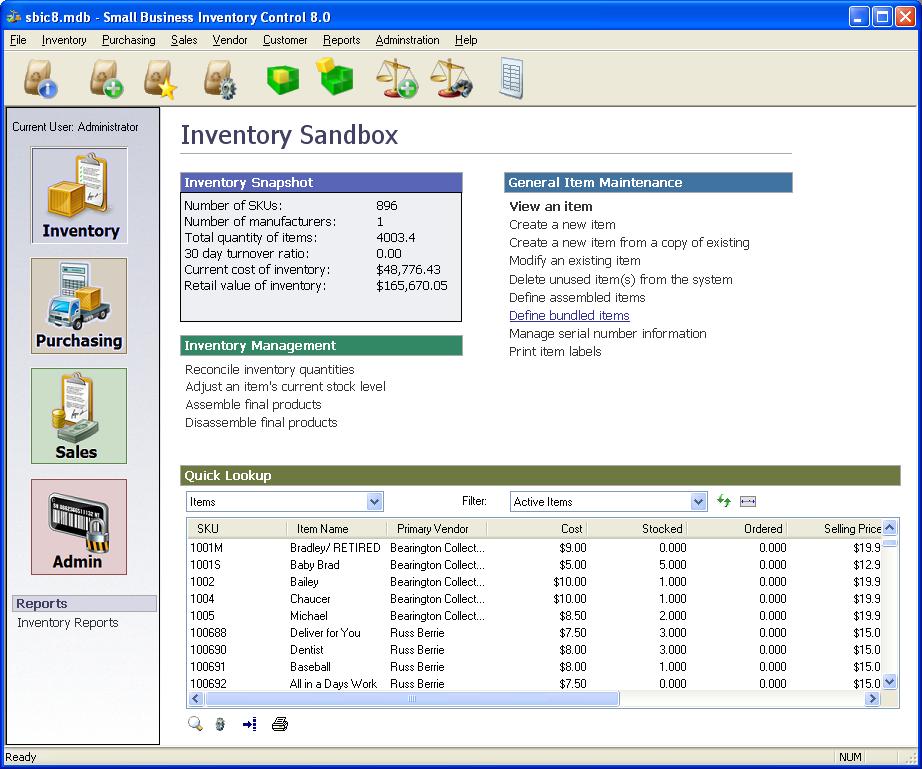

Inventory management systems (IMS) are software solutions that help businesses track and manage their inventory levels. They can be used by online businesses of all sizes to improve efficiency, reduce costs, and increase profitability.

There are many benefits to using an IMS for online businesses. These benefits include:

- Improved accuracy: IMSs can help businesses track their inventory levels more accurately, which can reduce the risk of overstocking or understocking.

- Reduced costs: IMSs can help businesses reduce their inventory costs by optimizing inventory levels and reducing waste.

- Increased efficiency: IMSs can help businesses improve their efficiency by automating inventory management tasks, such as tracking inventory levels, generating purchase orders, and managing shipments.

- Improved customer service: IMSs can help businesses improve their customer service by providing real-time inventory information, which can help them meet customer demand and avoid backorders.

When choosing an IMS, it is important to consider the following key features:

- Scalability: The IMS should be able to scale to meet the needs of a growing business.

- Integration: The IMS should be able to integrate with other business systems, such as accounting and CRM systems.

- Ease of use: The IMS should be easy to use for all users, regardless of their technical expertise.

- Support: The IMS should be supported by a team of experienced professionals who can provide help and guidance when needed.

There are many popular IMSs available for online businesses. Some of the most popular options include:

- NetSuite

- SAP Business One

- Oracle NetSuite

- Sage 50cloud

- Zoho Inventory

Inventory Optimization Techniques

Inventory optimization is crucial for online businesses to minimize costs, enhance customer satisfaction, and ensure operational efficiency. It involves determining the optimal inventory levels to meet demand while minimizing waste and storage expenses.

To optimize inventory, businesses can adopt various strategies. One approach is to implement a just-in-time (JIT) inventory system, which reduces inventory holding costs by ordering only the necessary quantities as they are needed. This approach requires accurate demand forecasting and close coordination with suppliers.

Data Analytics in Inventory Optimization

Data analytics plays a vital role in inventory optimization. By analyzing historical sales data, demand patterns, and customer behavior, businesses can make informed decisions about inventory levels. Predictive analytics can help forecast future demand, allowing businesses to adjust their inventory accordingly.

Additionally, businesses can use data analytics to identify slow-moving or obsolete items. By analyzing sales trends and inventory turnover rates, they can determine which items are not selling well and take appropriate actions, such as offering discounts or discontinuing the product.

Inventory Tracking and Control

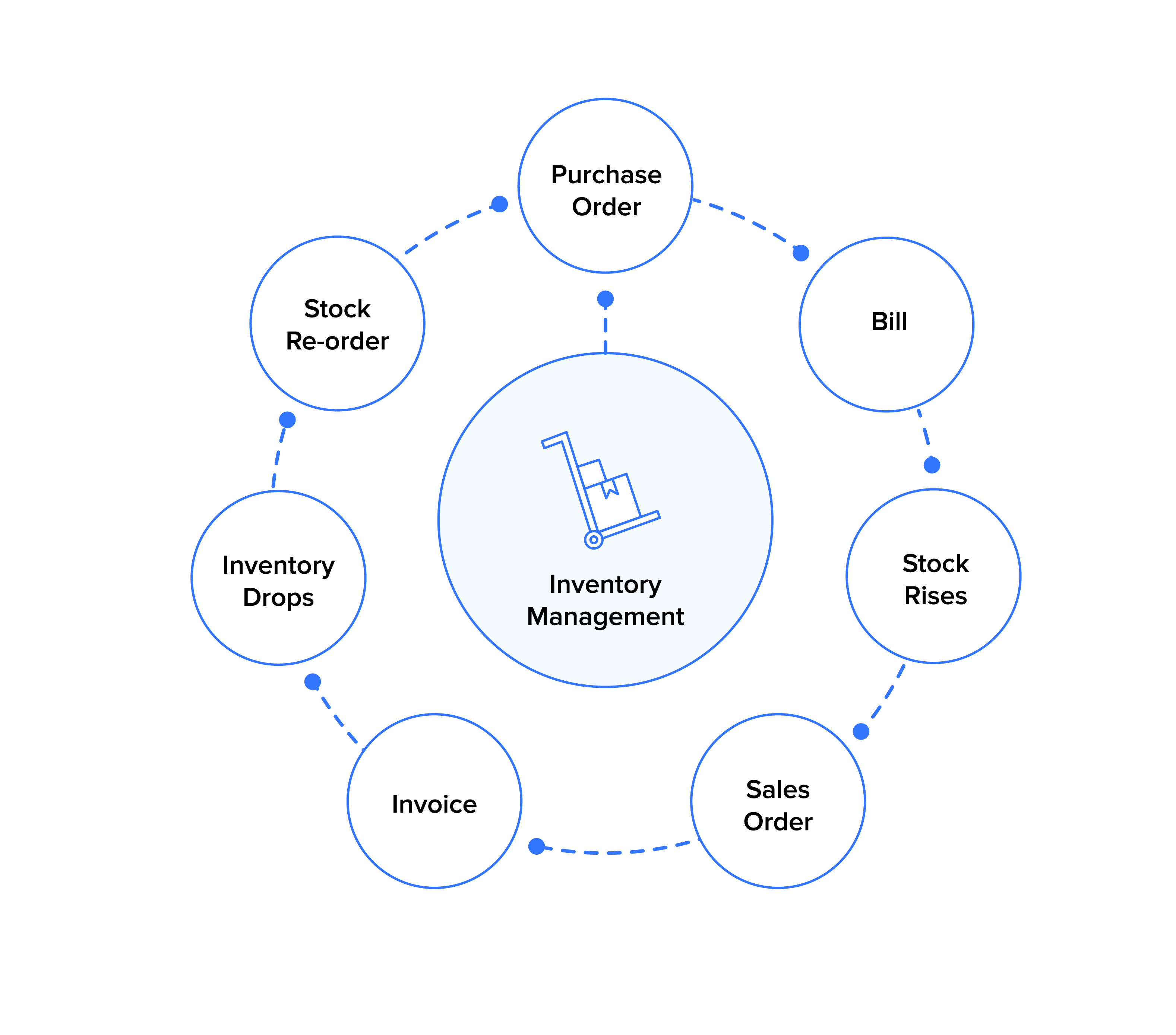

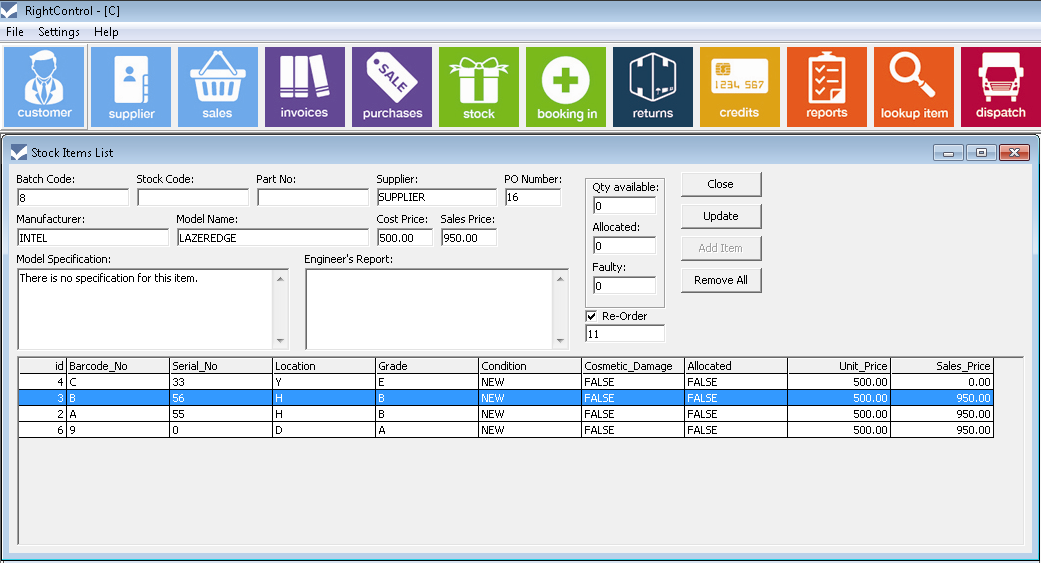

Inventory tracking and control are crucial for online businesses to maintain accurate inventory records, prevent stockouts, and optimize operations.

Various methods are used for tracking inventory, including:

- Manual tracking:Using spreadsheets or physical records to record inventory levels.

- Barcode scanning:Using barcode scanners to capture inventory data and update records.

- Radio frequency identification (RFID):Using RFID tags and readers to track inventory in real-time.

- Inventory management software:Using specialized software to manage inventory, track levels, and generate reports.

To control inventory levels and prevent stockouts, businesses can implement the following procedures:

- Establish safety stock levels:Determine the minimum inventory levels required to meet demand and avoid stockouts.

- Monitor inventory levels regularly:Track inventory levels using the chosen method and monitor them closely to identify potential shortages.

- Forecast demand:Use historical data and industry trends to predict future demand and adjust inventory levels accordingly.

- Implement inventory optimization techniques:Use techniques like just-in-time (JIT) or vendor-managed inventory (VMI) to optimize inventory levels and reduce costs.

Best practices for inventory tracking and control include:

- Use a combination of tracking methods:Employ multiple methods to ensure accuracy and redundancy.

- Automate inventory management:Use inventory management software to automate processes and reduce errors.

- Conduct regular inventory audits:Verify inventory records against physical counts to ensure accuracy.

- Train staff on inventory management:Ensure that staff is properly trained on inventory tracking and control procedures.

Inventory Forecasting and Planning: Business Inventory Online

Inventory forecasting and planning are crucial aspects of inventory management that enable businesses to anticipate future demand and optimize inventory levels. Effective forecasting and planning help businesses meet customer needs while minimizing the risks of overstocking or understocking.

Inventory forecasting involves predicting future demand for specific items based on historical data, market trends, and other relevant factors. Various techniques are used for forecasting, including time series analysis, regression analysis, and machine learning algorithms.

Inventory Forecasting Techniques

- Time Series Analysis:This technique analyzes historical demand patterns to identify trends, seasonality, and other patterns that can be used to forecast future demand.

- Regression Analysis:This technique establishes a mathematical relationship between demand and independent variables such as price, advertising, and economic indicators.

- Machine Learning Algorithms:These algorithms, such as neural networks and support vector machines, can learn complex patterns in historical data and make accurate forecasts.

Once inventory demand is forecasted, businesses can develop an inventory plan that Artikels the target inventory levels, safety stock levels, and replenishment strategies. Inventory planning considers factors such as lead times, demand variability, and desired service levels to ensure that inventory is available when needed without excessive stockpiles.

Framework for Effective Inventory Planning

- Establish Target Inventory Levels:Determine the optimal inventory levels based on forecasted demand, lead times, and desired service levels.

- Set Safety Stock Levels:Establish a buffer stock to mitigate the risk of stockouts due to demand fluctuations or supply chain disruptions.

- Develop Replenishment Strategies:Define the frequency and quantity of inventory replenishment based on demand patterns and lead times.

- Monitor and Adjust:Regularly track inventory levels and demand patterns to make adjustments to the plan as needed.

By implementing effective inventory forecasting and planning processes, businesses can optimize their inventory management, reduce costs, improve customer satisfaction, and gain a competitive advantage.

Inventory Replenishment Strategies

Inventory replenishment strategies are critical for online businesses to ensure they have the right amount of stock to meet customer demand without overstocking or running out of inventory. There are several different inventory replenishment strategies available, each with its own advantages and disadvantages.

The choice of inventory replenishment strategy depends on a number of factors, including the nature of the business, the products being sold, the customer demand, and the cost of holding inventory. Some of the most common inventory replenishment strategies include:

Fixed-time replenishment, Business inventory online

With fixed-time replenishment, inventory is replenished at regular intervals, regardless of the current inventory level. This strategy is simple to implement and can help to ensure that inventory levels are always maintained at a certain level. However, it can also lead to overstocking if demand is low or understocking if demand is high.

Fixed-order quantity

With fixed-order quantity, a fixed number of units are ordered each time inventory is replenished. This strategy is simple to implement and can help to ensure that inventory levels are not excessive. However, it can also lead to stockouts if demand is higher than expected.

Periodic review

With periodic review, inventory levels are reviewed at regular intervals and orders are placed to bring inventory levels up to a predetermined target level. This strategy is more complex to implement than fixed-time replenishment or fixed-order quantity, but it can be more effective at preventing overstocking and stockouts.

Min-max

With min-max, inventory is replenished when the inventory level falls below a minimum level. This strategy is simple to implement and can help to ensure that inventory levels are never too low. However, it can also lead to overstocking if demand is low.

Examples of successful inventory replenishment strategies used by online businesses:

- Amazon uses a combination of fixed-time replenishment and periodic review to manage its inventory.

- Zappos uses a fixed-order quantity strategy to manage its inventory.

- Walmart uses a min-max strategy to manage its inventory.

Epilogue

In conclusion, business inventory online is a multifaceted discipline that requires a strategic approach to ensure seamless operations and customer satisfaction. By implementing robust inventory management systems, optimizing inventory levels, and leveraging data analytics, online businesses can transform their inventory management practices, unlocking new levels of efficiency and profitability.

Query Resolution

What are the benefits of using an inventory management system for online businesses?

Inventory management systems streamline inventory processes, minimize errors, provide real-time visibility into stock levels, and facilitate data-driven decision-making.

How can I optimize inventory levels to reduce costs and improve customer satisfaction?

Inventory optimization techniques involve analyzing historical data, forecasting demand, and implementing safety stock levels to minimize overstocking and stockouts, ensuring optimal stock levels at all times.

What are some best practices for inventory tracking and control?

Best practices for inventory tracking and control include regular inventory audits, cycle counting, and implementing inventory control systems to prevent stockouts and ensure accurate stock records.