The business inventory management system is a crucial tool for businesses of all sizes, enabling them to effectively manage their inventory levels, streamline operations, and optimize their supply chains. In this comprehensive guide, we will delve into the intricacies of inventory management systems, exploring their benefits, key components, and best practices.

From manufacturing and retail to healthcare and hospitality, businesses across diverse industries rely on inventory management systems to ensure accurate inventory tracking, prevent stockouts, and optimize their operations. These systems provide real-time visibility into inventory levels, enabling businesses to make informed decisions, reduce waste, and enhance customer satisfaction.

Business Inventory Management System Overview

Inventory management systems are essential tools for businesses of all sizes. They help businesses track their inventory levels, manage their supply chain, and optimize their operations. A good inventory management system can help businesses save money, improve efficiency, and increase customer satisfaction.Inventory management systems are used in a wide variety of industries, including retail, manufacturing, and healthcare.

Some common examples of businesses that use inventory management systems include:

- Retail stores

- Manufacturers

- Warehouses

- Distribution centers

- Hospitals

- Pharmacies

Key features and functionalities of a typical inventory management system include:

- Inventory tracking

- Purchase order management

- Receiving and put-away

- Shipping and order fulfillment

- Inventory forecasting

- Cycle counting

- Reporting

Types of Inventory Management Systems

Inventory management systems play a crucial role in optimizing inventory levels, reducing costs, and enhancing operational efficiency. There are different types of inventory management systems, each with its own advantages and disadvantages. Understanding these systems is essential for businesses to select the most appropriate one based on their specific needs.

Perpetual Inventory Systems

Perpetual inventory systems continuously track inventory levels in real-time. They use a combination of physical counts and electronic records to maintain accurate inventory data. This allows businesses to have a clear and up-to-date view of their inventory at all times.

Advantages:* Real-time inventory visibility

- Improved accuracy

- Reduced risk of stockouts

- Enhanced forecasting capabilities

Disadvantages:* Can be more complex and expensive to implement

Requires regular physical counts for verification

Suitable for:Businesses with high-volume inventory, fast-moving items, or a need for accurate inventory tracking.

Periodic Inventory Systems

Periodic inventory systems rely on periodic physical counts to determine inventory levels. These counts are typically conducted at regular intervals, such as monthly or quarterly. The system then uses the count data to update inventory records. Advantages:* Simpler and less expensive to implement

Suitable for businesses with low-volume inventory or slow-moving items

Disadvantages:* Does not provide real-time inventory visibility

- Risk of stockouts if physical counts are not conducted regularly

- Limited forecasting capabilities

Suitable for:Businesses with stable inventory levels, low inventory turnover, or a limited need for accurate inventory tracking.

Hybrid Inventory Systems

Hybrid inventory systems combine elements of both perpetual and periodic systems. They use a combination of real-time tracking and periodic physical counts to maintain inventory accuracy. Advantages:* Provides a balance between real-time visibility and cost-effectiveness

Reduces the risk of stockouts while maintaining inventory accuracy

Disadvantages:* Can be more complex to implement and manage

Requires both real-time tracking and periodic physical counts

Suitable for:Businesses with moderate inventory levels, a mix of fast- and slow-moving items, or a need for both real-time visibility and cost-effectiveness.

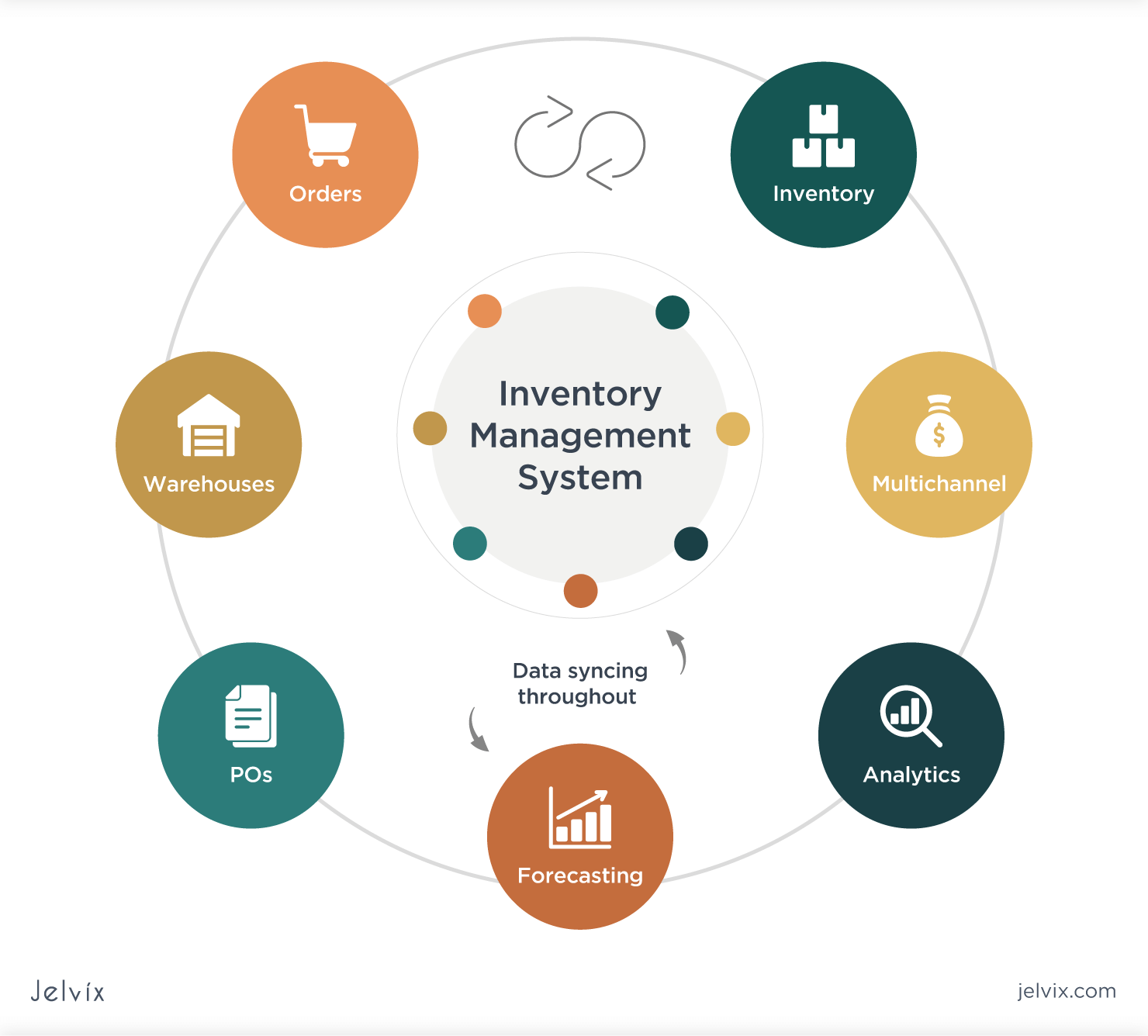

Key Components of an Inventory Management System

An inventory management system is a software solution that helps businesses track, manage, and optimize their inventory levels. It consists of several core components that work together to provide a comprehensive view of the inventory and facilitate efficient management.

The key components of an inventory management system include:

Inventory Tracking

Inventory tracking is the process of monitoring the quantity and location of items in stock. An inventory management system typically uses a database to store this information, which can be accessed by authorized users to view real-time inventory levels.

Stock Level Monitoring

Stock level monitoring is the process of tracking inventory levels to ensure that there is always enough stock to meet demand. An inventory management system can be set to automatically generate alerts when stock levels fall below a certain threshold, allowing businesses to take action to replenish stock before it runs out.

Reordering and Forecasting

Reordering and forecasting are two important components of inventory management. Reordering involves placing orders for new stock when inventory levels fall below a certain threshold. Forecasting is the process of predicting future demand for inventory items based on historical data and other factors.

This information can be used to optimize reordering decisions and ensure that businesses have the right amount of stock on hand to meet demand.

Reporting and Analytics

Reporting and analytics are essential for understanding inventory performance and making informed decisions. An inventory management system can generate a variety of reports, such as inventory turnover reports, stock level reports, and reorder reports. These reports can be used to identify trends, analyze inventory performance, and make improvements to the inventory management process.

Benefits of Using an Inventory Management System

An inventory management system offers a plethora of advantages for businesses seeking to optimize their operations. By implementing such a system, organizations can reap the following benefits:

Improved Inventory Accuracy

Accurate inventory records are the cornerstone of efficient inventory management. An inventory management system automates inventory tracking, reducing the risk of human error and ensuring that inventory levels are always up-to-date. This eliminates discrepancies between physical inventory and system records, leading to improved decision-making and reduced losses due to overstocking or stockouts.

Reduced Stockouts and Overstocking

Inventory management systems provide real-time visibility into inventory levels, enabling businesses to identify potential stockouts and overstocking situations. By analyzing historical demand data and using forecasting techniques, these systems can generate accurate demand forecasts and optimize inventory levels accordingly. This helps businesses maintain optimal inventory levels, reducing the risk of stockouts that can lead to lost sales and customer dissatisfaction, as well as overstocking that can tie up valuable resources and result in inventory write-downs.

Enhanced Supply Chain Visibility, Business inventory management system

Inventory management systems provide a centralized platform for managing inventory across multiple locations and warehouses. This enhanced visibility enables businesses to track the movement of goods throughout the supply chain, from suppliers to warehouses to retail stores. By integrating with other supply chain management systems, such as enterprise resource planning (ERP) systems, inventory management systems can provide a comprehensive view of inventory levels, order status, and supplier performance.

This visibility allows businesses to identify and address potential supply chain disruptions, optimize inventory allocation, and improve collaboration with suppliers.

Increased Operational Efficiency

Inventory management systems automate many of the tasks associated with inventory management, such as inventory tracking, order processing, and inventory replenishment. This automation reduces the need for manual labor, saving time and resources. Additionally, by providing real-time inventory visibility, inventory management systems enable businesses to make informed decisions about inventory levels, order quantities, and supplier selection.

This streamlined and efficient approach to inventory management can lead to significant cost savings and improved operational performance.

Challenges in Implementing an Inventory Management System

Implementing an inventory management system (IMS) can bring significant benefits to businesses, but it also comes with its set of challenges. Understanding and addressing these challenges is crucial for a successful implementation and to maximize the system’s potential.

Common challenges businesses face when implementing an IMS include:

Data Accuracy and Integration

Ensuring data accuracy and seamless integration with existing systems is a key challenge. Inaccurate data can lead to incorrect inventory levels, order fulfillment issues, and poor decision-making. Integrating the IMS with other systems, such as accounting, sales, and purchasing, is essential to maintain data consistency and avoid manual errors.

System Customization and Training

Customizing the IMS to meet specific business requirements and training staff on the new system are crucial. Off-the-shelf IMS may not fully align with unique business processes, and customization is often necessary. Proper training ensures that staff understands the system’s functionality and can use it effectively.

Process and Workflow Changes

Implementing an IMS often requires changes to existing processes and workflows. Businesses may need to adjust inventory management practices, such as receiving, storing, and shipping, to align with the new system. Effective communication and change management strategies are essential to ensure smooth transitions and minimize disruptions.

Best Practices for Inventory Management

Effective inventory management is crucial for businesses to maintain optimal stock levels, reduce costs, and enhance customer satisfaction. Here are some best practices to guide effective inventory management:

Establishing clear inventory policies is essential to ensure consistent and efficient management practices. These policies should define inventory goals, stock levels, reorder points, and inventory valuation methods.

Optimizing Stock Levels

- Implement a safety stock level to buffer against unexpected demand fluctuations and supply chain disruptions.

- Use inventory forecasting techniques to predict future demand and adjust stock levels accordingly.

- Employ the ABC analysis to classify inventory items based on their value and demand, allowing for targeted inventory management strategies.

Implementing Inventory Control Techniques

- Conduct regular inventory audits to ensure accuracy and identify discrepancies.

- Implement first-in, first-out (FIFO) or last-in, first-out (LIFO) inventory costing methods to manage inventory valuation.

- Use cycle counting to verify inventory levels on a regular basis and identify potential issues early on.

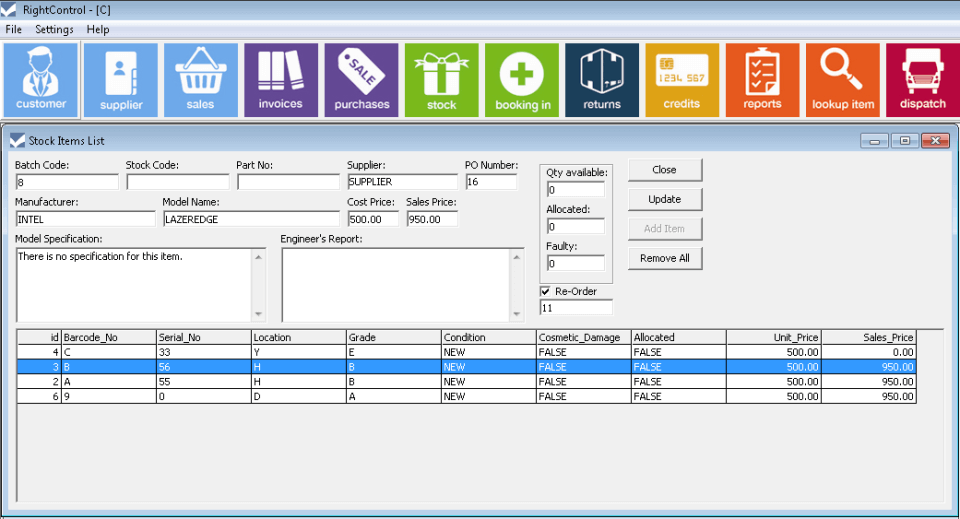

Utilizing Technology and Automation

- Implement an inventory management software system to automate inventory tracking, forecasting, and replenishment.

- Use barcode scanners or RFID technology to improve inventory accuracy and efficiency.

- Integrate inventory management with other business systems, such as sales and accounting, for seamless data flow and real-time updates.

Future Trends in Inventory Management

Inventory management is constantly evolving, with new technologies and trends emerging all the time. Some of the most important future trends in inventory management include:

Artificial Intelligence and Machine Learning

Artificial intelligence (AI) and machine learning (ML) are already being used to improve inventory management in a number of ways. For example, AI can be used to:

- Predict demand

- Optimize inventory levels

- Automate inventory management tasks

As AI and ML continue to develop, they will become even more powerful tools for inventory managers. For example, AI could be used to create virtual inventory assistants that can help managers make better decisions about inventory management.

Cloud-Based Inventory Management Systems

Cloud-based inventory management systems are becoming increasingly popular. These systems offer a number of advantages over traditional on-premises systems, including:

- Scalability

- Flexibility

- Cost-effectiveness

As cloud computing continues to mature, cloud-based inventory management systems will become even more popular.

Blockchain Technology

Blockchain technology is a distributed ledger system that has the potential to revolutionize a number of industries, including inventory management. Blockchain can be used to create a secure and transparent record of inventory transactions. This could help to reduce fraud and improve the efficiency of inventory management.

As blockchain technology continues to develop, it is likely to become more widely adopted for inventory management.

Wrap-Up

In conclusion, implementing a robust business inventory management system is essential for businesses seeking to optimize their inventory operations, improve efficiency, and gain a competitive edge. By leveraging the capabilities of these systems, businesses can effectively manage their inventory levels, reduce costs, and enhance their overall profitability.

Essential FAQs

What are the key benefits of using a business inventory management system?

Improved inventory accuracy, reduced stockouts and overstocking, enhanced supply chain visibility, and increased operational efficiency.

What are the different types of inventory management systems available?

Perpetual, periodic, and hybrid systems.

What are the core components of an inventory management system?

Inventory tracking, stock level monitoring, reordering and forecasting, and reporting and analytics.

What are the common challenges businesses face when implementing an inventory management system?

Data accuracy and integration, system customization and training, and process and workflow changes.