Business inventory management is the cornerstone of efficient operations, ensuring businesses have the right products, in the right quantities, at the right time. Effective inventory management empowers businesses to optimize costs, enhance customer satisfaction, and drive profitability.

From traditional methods to cutting-edge technology, this comprehensive guide delves into the world of inventory management, exploring strategies, best practices, and emerging trends that shape the future of inventory management.

Business Inventory Management Overview

Business inventory management refers to the process of acquiring, storing, and tracking goods and materials within a business. Effective inventory management ensures that businesses have the right amount of inventory to meet customer demand while minimizing costs.

Effective inventory management is crucial for businesses as it helps them:

- Avoid stockouts and meet customer demand

- Minimize storage costs and optimize space utilization

- Reduce waste and spoilage

- Improve cash flow and profitability

- Enhance supply chain efficiency

Inventory Management Methods

Inventory management methods are strategies used by businesses to optimize their inventory levels. Different methods suit different business needs and objectives. Here are some common inventory management methods and their pros and cons:

Just-in-Time (JIT)

- Objective:Minimize inventory levels and only order materials as needed for production.

- Pros:

- Reduced inventory costs

- Improved cash flow

- Increased efficiency and reduced waste

- Cons:

- Higher risk of stockouts

- Potential for production delays

- Increased dependence on suppliers

Periodic Inventory System

- Objective:Track inventory levels at regular intervals, typically monthly or quarterly.

- Pros:

- Simplicity and ease of implementation

- Lower cost compared to perpetual inventory systems

- Suitable for businesses with stable demand and low inventory turnover

- Cons:

- Inaccurate inventory data between counting periods

- Potential for stockouts or overstocking

- Labor-intensive and time-consuming

Perpetual Inventory System

- Objective:Continuously track inventory levels in real-time.

- Pros:

- Accurate and up-to-date inventory data

- Improved stock management and reduced stockouts

- Better control over inventory levels and costs

- Cons:

- Higher implementation and maintenance costs

- Requires advanced inventory management software

- Potential for errors if not properly implemented

Safety Stock

- Objective:Maintain a buffer of extra inventory to protect against unexpected demand or supply disruptions.

- Pros:

- Reduces the risk of stockouts

- Ensures smooth production and operations

- Provides flexibility to handle fluctuations in demand

- Cons:

- Increased inventory costs

- Potential for obsolescence or spoilage

- Reduced inventory turnover and efficiency

First-In, First-Out (FIFO)

- Objective:Sell the oldest inventory first.

- Pros:

- Prevents obsolescence and spoilage

- Matches the flow of goods

- Simplifies inventory valuation

- Cons:

- Can lead to higher inventory costs during periods of inflation

- Not suitable for perishable goods

- May result in higher shipping costs

Last-In, First-Out (LIFO)

- Objective:Sell the most recently acquired inventory first.

- Pros:

- Reduces inventory costs during periods of inflation

- Suitable for perishable goods

- Simplifies inventory valuation

- Cons:

- Can lead to higher inventory costs during periods of deflation

- Not suitable for businesses with high inventory turnover

- May result in higher shipping costs

Inventory Management Strategies

Inventory management strategies are essential for optimizing inventory levels and minimizing inventory costs. These strategies help businesses maintain the right amount of inventory to meet customer demand while minimizing waste and costs.

Optimizing Inventory Levels

- Safety Stock:Maintain a buffer of inventory to protect against unexpected demand fluctuations or supply chain disruptions.

- Economic Order Quantity (EOQ):Calculate the optimal quantity to order at a time to minimize total inventory costs.

- Just-in-Time (JIT) Inventory:Reduce inventory levels by ordering only what is needed, when it is needed.

Minimizing Inventory Costs

- Vendor Consolidation:Reduce the number of suppliers to simplify ordering and improve negotiation power.

- Bulk Discounts:Negotiate discounts for larger orders to reduce per-unit costs.

- Inventory Tracking and Analysis:Monitor inventory levels and identify slow-moving or obsolete items to reduce waste.

Inventory Management Technology

Technology plays a crucial role in modern inventory management, automating processes, improving accuracy, and providing real-time visibility into inventory levels.

Various types of inventory management software are available, each tailored to specific business needs and industry requirements.

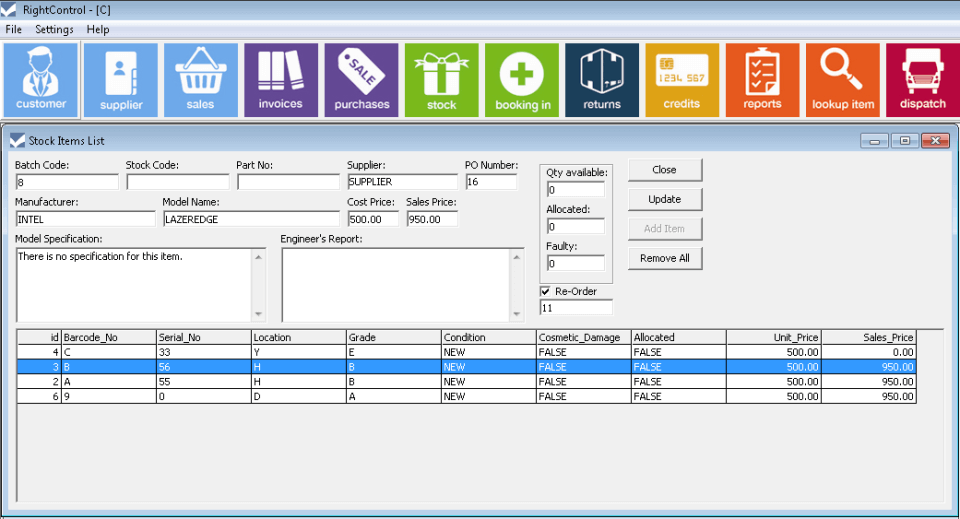

Inventory Management Software

- Warehouse Management Systems (WMS):Comprehensive software that manages all aspects of warehouse operations, including inventory tracking, order fulfillment, and shipping.

- Enterprise Resource Planning (ERP) Systems:Integrated software suites that manage various business functions, including inventory management as a module.

- Inventory Optimization Software:Specialized software that analyzes inventory data to determine optimal stock levels, reorder points, and safety stock levels.

- Radio Frequency Identification (RFID) Systems:Automated systems that use RFID tags to track inventory items, providing real-time visibility and reducing manual counting errors.

- Cloud-Based Inventory Management Software:Software hosted on the cloud, providing remote access and scalability for businesses with multiple locations or complex inventory needs.

Inventory Management Best Practices

Effective inventory management is crucial for businesses to optimize operations, minimize costs, and enhance customer satisfaction. By implementing best practices, organizations can establish efficient inventory control systems that ensure optimal stock levels, reduce waste, and improve overall profitability.

Accurate Inventory Records, Business inventory management

Maintaining accurate inventory records is fundamental to effective inventory management. This involves regularly updating stock levels, tracking incoming and outgoing items, and conducting periodic inventory counts. Accurate records provide real-time visibility into inventory status, enabling businesses to make informed decisions about replenishment and avoid stockouts.

- Regularly reconcile inventory records with physical counts.

- Use inventory management software to automate tracking and updates.

- Implement barcode scanning or RFID technology for efficient data capture.

- Establish clear procedures for receiving, storing, and issuing inventory.

Inventory Management Challenges

Inventory management is a critical aspect of business operations, but it can also be challenging. Common challenges include:

- Inaccurate inventory records

- Overstocking or understocking

- Theft or damage

- Seasonality

- Lack of visibility into inventory levels

Overcoming these challenges requires a combination of effective inventory management practices and technology.

Overcoming Inventory Management Challenges

Inaccurate inventory records

Implement regular inventory audits to ensure accuracy.

Overstocking or understocking

Use forecasting techniques to predict demand and optimize inventory levels.

Theft or damage

Implement security measures and train staff on proper inventory handling.

Seasonality

Adjust inventory levels based on seasonal demand patterns.

Lack of visibility into inventory levels

Use inventory management software to provide real-time visibility into inventory levels.

Inventory Management Trends

Inventory management is constantly evolving, with new trends emerging all the time. These trends are being driven by a number of factors, including the rise of e-commerce, the increasing complexity of supply chains, and the need for businesses to be more efficient and responsive.

Some of the most important inventory management trends include:

Just-in-time (JIT) inventory management

JIT inventory management is a strategy that seeks to minimize the amount of inventory on hand by only ordering items when they are needed. This can help businesses to reduce their carrying costs and improve their cash flow.

Vendor-managed inventory (VMI)

VMI is a strategy in which the supplier manages the inventory for the customer. This can help businesses to improve their inventory accuracy and reduce their inventory costs.

Radio frequency identification (RFID)

RFID is a technology that uses radio waves to track the movement of inventory items. This can help businesses to improve their inventory accuracy and efficiency.

Cloud-based inventory management systems

Cloud-based inventory management systems are software applications that are hosted in the cloud. This can make them more accessible and affordable for businesses of all sizes.

Big data and analytics

Big data and analytics can be used to improve inventory management by providing businesses with insights into their inventory data. This can help businesses to make better decisions about their inventory levels and ordering patterns.

These are just a few of the most important inventory management trends. As these trends continue to evolve, they will have a significant impact on the way that businesses manage their inventory.

Epilogue: Business Inventory Management

By embracing a proactive approach to inventory management, businesses can unlock a wealth of benefits, including reduced costs, improved cash flow, and enhanced customer service. As technology continues to advance and trends evolve, businesses that stay abreast of these developments will be well-positioned to thrive in an increasingly competitive landscape.

Questions and Answers

What is the importance of inventory management?

Effective inventory management helps businesses optimize stock levels, reduce costs, improve customer satisfaction, and enhance overall operational efficiency.

What are the different inventory management methods?

Common inventory management methods include FIFO (First-In, First-Out), LIFO (Last-In, First-Out), and JIT (Just-In-Time) inventory management.

How can technology enhance inventory management?

Inventory management software can automate tasks, provide real-time data, and offer advanced analytics to optimize inventory levels and improve decision-making.